Supply chain knowledge is the process for improving a firm's business supply chain with expertise and knowledge. Supply chain learning includes everything from inventory, logistics and warehousing up to procurement. Supply chain learning has the purpose of improving the efficiency of business processes, like delivering products at the right time and price.

On-campus courses in colleges and universities, or online platforms are all ways to study supply chain management. These platforms let students take classes at their own pace and can be a great way for students to earn certifications in a specific supply chain topic or career path.

The UT Dallas Supply Chain Learning Center offers a variety of courses for students to choose from, as well as an online community to engage with fellow students and professors. This resource offers a place for students to network with supply chain professionals as well as find out about career opportunities.

Perspective Course: Each company in the supply chain contributes to a successful product. This perspective course explores the ways in which the digital economy affects companies' supply chains. It also examines what these changes mean to businesses.

This course would be ideal for those who are interested in the future impact of the supply-chain on their professional life.

Coursera's supply chain course offers a self-paced, free option for those who wish to learn the fundamentals of supply chain management. It contains short videos and interactive exercises that give a comprehensive introduction to the field.

In addition, the Coursera supply chain course features case studies that demonstrate how supply chains are changing as a result of technological advancements and economic factors.

Coursera’s Online Platform allows students the opportunity to complete courses from top universities in their own homes or offices. The platform is designed to be user-friendly, with interactive video lessons, exercises, quizzes, and more.

Supply Chain Coursera, a high-quality free online education platform, partners with leading universities all over the world. The platform offers courses taught by professors from top institutions.

This free course will teach students the fundamentals of supply chains and their importance to an organization. The course will teach students how to use key supply chain technologies and management systems.

It is important to learn how to manage product, financial and informational data. It is a vital skill for any supply chain manager who wishes to succeed.

Supply chain management is an ever-evolving field, which requires continuous training to stay competitive and current. It is important to provide your employees with quality supply chain training. If you give your workforce the right training, and create a supportive environment for them, they will have the knowledge to succeed.

FAQ

What is manufacturing and logistics?

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

How can we improve manufacturing efficiency?

First, we need to identify which factors are most critical in affecting production times. The next step is to identify the most important factors that affect production time. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you've identified them, try to find solutions for each of those factors.

What are the responsibilities of a logistic manager?

Logistics managers ensure that goods arrive on time and are unharmed. This is done through his/her expertise and knowledge about the company's product range. He/she also needs to ensure adequate stock to meet demand.

Why automate your warehouse

Automation has become increasingly important in modern warehousing. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses should be able adapt quickly to new needs. To do so, they must invest heavily in technology. Automating warehouses is a great way to save money. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety is boosted

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

It makes workers more efficient

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

Ensures quality products are delivered on time

-

Removes human error

-

It helps ensure compliance with regulations

What are the main products of logistics?

Logistics refers to all activities that involve moving goods from A to B.

They encompass all aspects transport, including packaging and loading, transporting, storage, unloading.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

What is it like to manage a logistics company?

It takes a lot of skills and knowledge to run a successful logistics business. To communicate effectively with clients and suppliers, you must be able to communicate well. You will need to know how to interpret data and draw conclusions. You must be able to work well under pressure and handle stressful situations. In order to innovate and create new ways to improve efficiency, creativity is essential. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

It is also important to be efficient and well organized in order meet deadlines.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

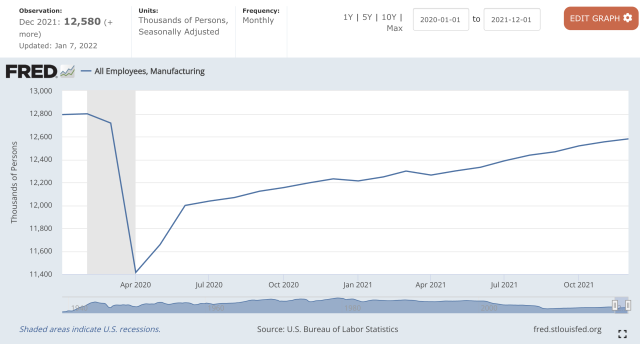

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation developed the 5S method in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. Because workers know what they can expect, this helps them perform their jobs more efficiently.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step requires a different action, which increases efficiency. You can make it easy for people to find things later by sorting them. When you set items in an order, you put items together. You then organize your inventory in groups. Labeling your containers will ensure that everything is correctly labeled.

Employees need to reflect on how they do their jobs. Employees should understand why they do the tasks they do, and then decide if there are better ways to accomplish them. They must learn new skills and techniques in order to implement the 5S system.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.