The United States' manufacturing sector has been a key contributor to the country's economy and employment. It is important that the United States, while still the third largest manufacturer in the world remains heavily dependent on other countries for most of its production needs. The United States is facing many challenges including a shortage of manufacturing capacity and a more competitive manufacturing environment. In order to strengthen our economy and address these challenges, the United States needs to strengthen its innovation system.

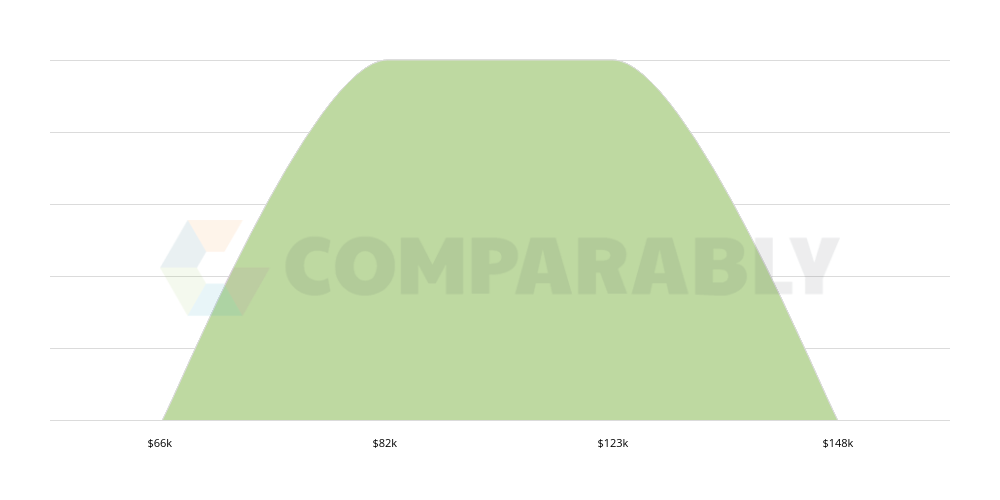

The United States has one of the highest manufacturing salaries in the country. The United States' manufacturing sector is the biggest contributor to the economy. It accounts for over 12 percent of gross domestic products (GDP) in the country and six percent of all US jobs. Although many believe manufacturing is dead, it has seen a revival.

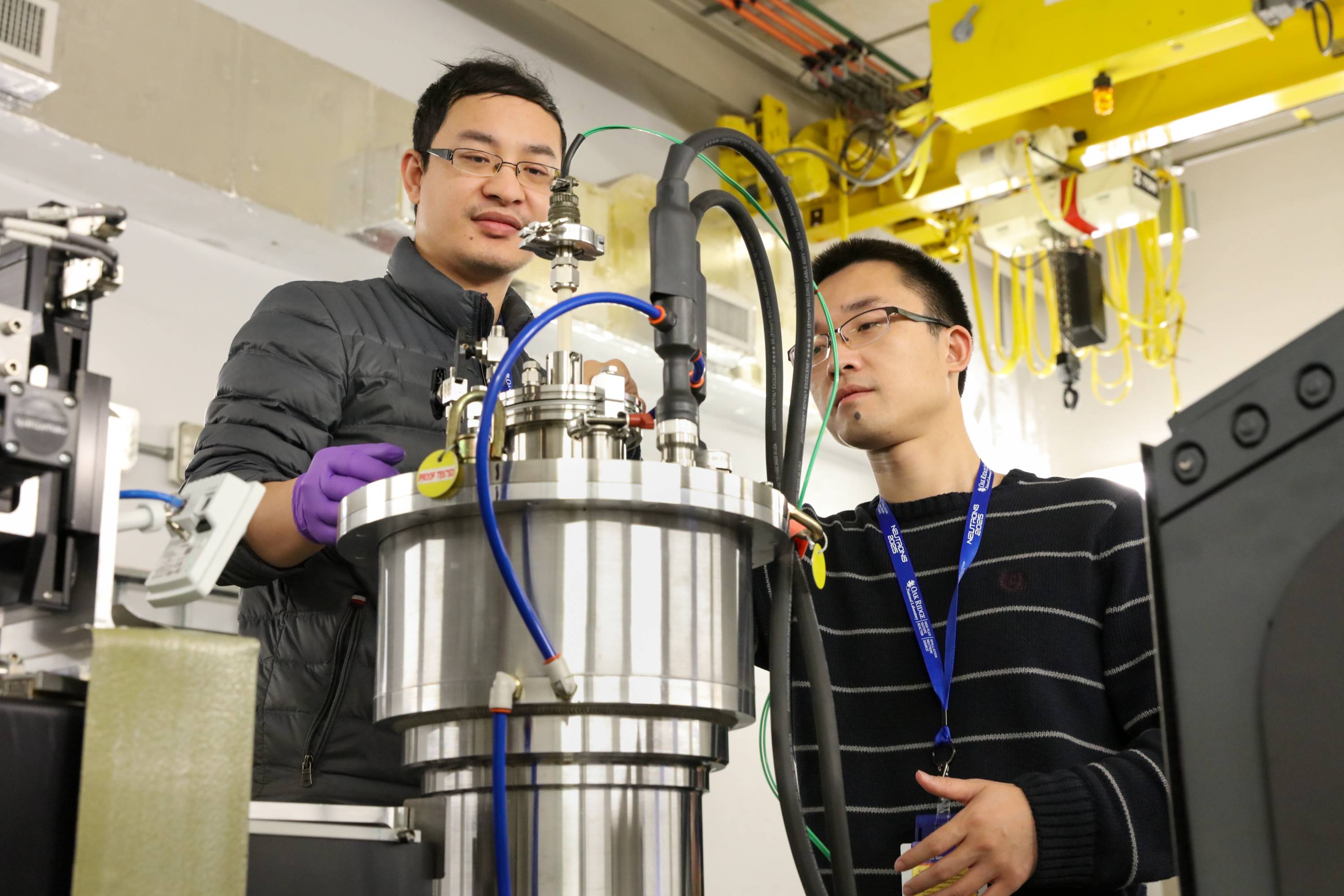

The United States' manufacturing industry has had a significant role for decades. In the United States, technology has helped companies produce more efficiently and quicker. The technology allows for lower costs through more efficient processes. American manufacturers also benefit from increased efficiency in production. This helps them to be more competitive.

The technology that is used in automation has also had an impact on the manufacturing sector. Automation has made it possible for more manufacturers to produce more efficiently and helped keep costs down.

Maintaining manufacturing in the United States is crucial for the security of our financial system. As many consumers consider environmental standards when purchasing goods, companies that produce their products in the United States are valued by their customers. Many consumers also value companies that hire their neighbors and support their local communities.

Manufacturing in the United States should be kept because it is more eco-friendly. The United States' manufacturing industry uses less energy than other countries. This has many advantages, including a reduced carbon footprint and the ability of goods being shipped to customers more efficiently. The United States keeps manufacturing local, which helps keep shipping and logistics costs low. Manufacturing in the United States can reduce shipping costs and improve customer service.

Finally, American manufacturing is a great way of supporting workers not located along the coasts. Many Americans have been affected by the economic downturn, which has resulted in many people being unemployed. This has also prompted a rise of interest in bringing production closer to the U.S. markets. There were over 22,000 manufacturing jobs created in America in the last 12 months. The future will see the American economy grow.

FAQ

What does it mean to be a manufacturer?

Manufacturing Industries are companies that manufacture products. These products are sold to consumers. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. These companies produce goods using raw materials and other equipment. This includes all types if manufactured goods.

What is the job of a logistics manger?

A logistics manager ensures that all goods are delivered on time and without damage. This is done by using his/her experience and knowledge of the company's products. He/she also needs to ensure adequate stock to meet demand.

What does warehouse refer to?

A warehouse or storage facility is where goods are stored before they are sold. You can have it indoors or outdoors. In some cases it could be both indoors and outdoors.

What is the difference between manufacturing and logistics

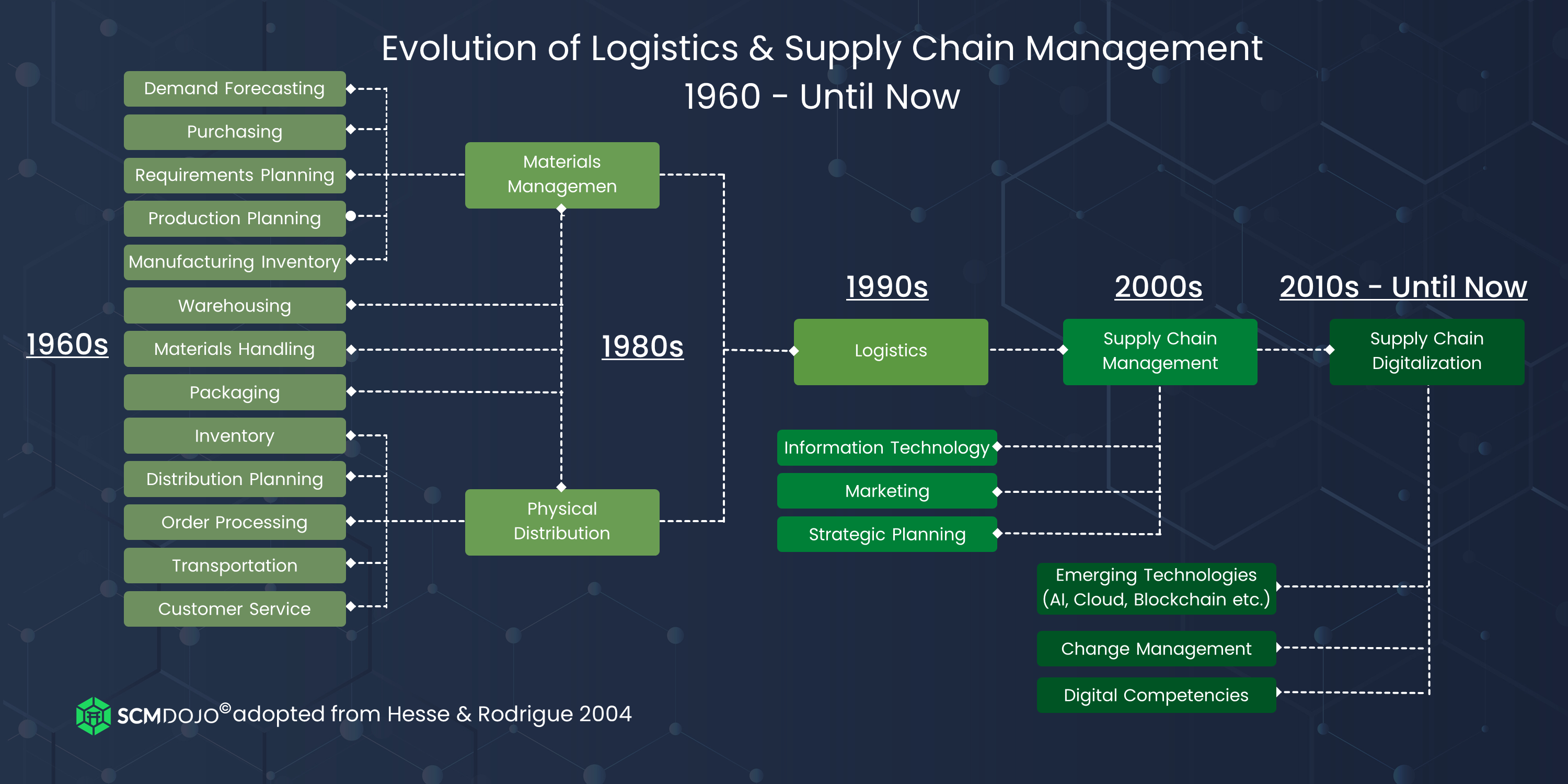

Manufacturing refers to the process of making goods using raw materials and machines. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Manufacturing and logistics can often be grouped together to describe a larger term that covers both the creation of products, and the delivery of them to customers.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was created in Japan by Taiichi Ohno during the 1970s and 80s. He received the Toyota Production System award (TPS), from Kanji Toyoda, founder of TPS. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Lean manufacturing is widely used in many industries. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

Lean manufacturing can be applied to almost every aspect of an organization. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three types of lean manufacturing.

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.