The manufacturing industry is booming and offers many job options. This industry is great for recent graduates as it requires a range of skills. In this article, we'll discuss why you should consider a career in manufacturing. Learn about the various types of jobs in this field. You'll find that manufacturing requires a variety of skills and has many benefits for its employees. These tips will help you find a great manufacturing job.

Manufacturing is a rapidly growing industry

The manufacturing industry is growing rapidly. More than half the manufacturing industry's activities involve inputs such as advertising and logistics. This means that for every dollar in manufacturing output, 19 cents have to be spent on service inputs. Half of the employees in this industry perform office support and/or service roles. This trend is expected to continue. To be competitive in the manufacturing industry, the right skills are essential. However, a degree in manufacturing may not be enough.

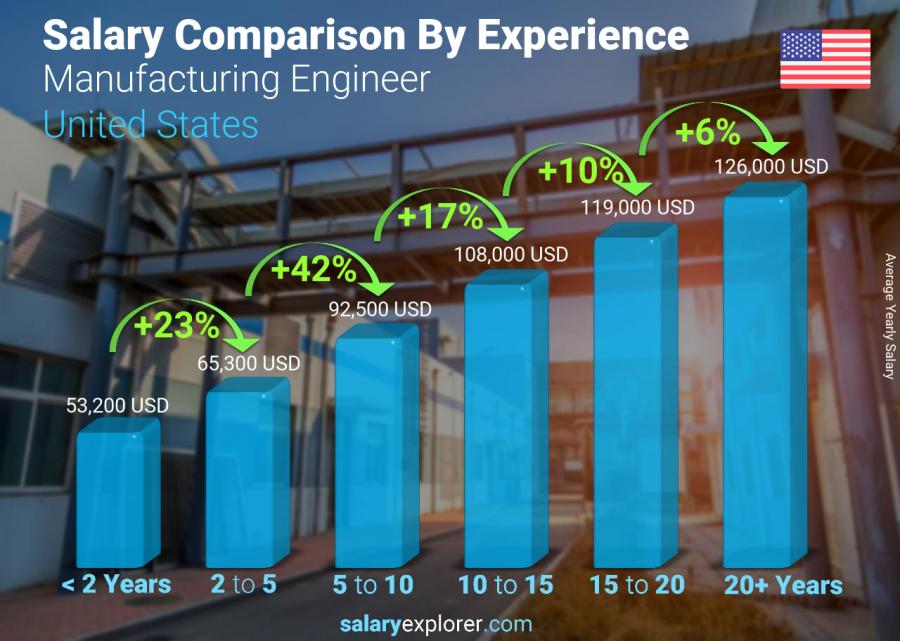

These sectors, which are important for economic development and have high levels of investment, are an attractive option for communities. These sectors are also vital sources of innovation. A lot of advanced manufacturing companies spend substantial amounts of money on research, development, and testing. High wages are also possible for these workers. In Texas, the average annual wage in manufacturing was $79700 in 2019.

This is a great choice for recent graduates

Although there are many jobs that may appeal to recent graduates in the workforce, manufacturing is a good option for them. This industry provides stability, job security, advancement opportunities, and a lot of opportunity. Manufacturing is secure and has a high skilled shortage as the baby boomers age. As many as 522,000 manufacturing positions will be unfilled by the end of 2019. This sector offers training to help you fill these jobs.

A career in manufacturing can lead you to various leadership and management positions. If you have the right training, it is possible to become a plant or machine operator. You could also move up to a more senior role. There is plenty of opportunity for growth in many manufacturing jobs. You can start as an entry-level production employee and eventually move up to a management position, or even become a manager. Many manufacturing jobs also offer the opportunity to climb up the ladder and become a manager.

You can find a wide range of employment opportunities here

Manufacturing is an industry that touches almost every facet of our lives, so there are many jobs available. Many different jobs are available in this industry, including entry level positions. This sector offers great potential for growth and most companies prefer to encourage employees from within. Manufacturing jobs can include machine operators, management, and even extensive training. This job is ideal for recent college graduate who want to enhance their experience, or look to change careers.

The manufacturing industry is experiencing rapid growth. Manufacturing is a major employer in technology innovation and manufacturing employs about 10 percent. Manufacturing has seen a rebound since the recession while other industries have stagnated. There will be nearly 500,000 manufacturing job openings by 2020. You will find many interesting job opportunities in manufacturing, along with a stable career path that is high-paying and secure.

This requires many skills.

Manufacturing jobs require a variety of skills, including management, interpersonal and technical. Fluency of dominant languages is a plus. You'll be likely to work with people whose first language other than English isn't English, as globalization is at its peak. Fluent communication in another language makes you a more valuable employee. Experience operating specialized machinery and other skills are also required. You can find out more information about manufacturing careers here. Listed below are some of the most popular skills for manufacturing workers.

For manufacturing jobs, speed and precision are essential. It is essential that employees are quick to learn and can be precise about details. Manufacturing operations depend on their workers to be reliable. They must also be punctual and give their best every day. Additionally, workers need to be able do their jobs independently. Reliability in these tasks can make a huge difference in the operation's overall efficiency. These traits make manufacturing jobs highly attractive to people who possess them.

It's in demand

Manufacturing has many entry-level positions. Entry-level positions allow people who have no experience to gain experience, build their professional networks, and develop their skills. This allows them to advance quickly through the company. It is not easy to get into entry-level roles, but it can help you build your career. They are not the only job opportunities in this industry. The following jobs are available in manufacturing.

Manufacturing is a rewarding career. You might have certain skills or talents. Many manufacturing careers require education and training. A high school diploma is required for electrical and electronic equipment technicians. Other requirements might include gaining experience, earning certification, or networking. No matter what type of manufacturing job you are looking for, you will need to be detail-oriented and able to solve problems.

It pays off

You are in the right place if you're looking to change careers in manufacturing. You can get high-paying, well-paid jobs in this field without much experience. As an entry-level warehouse worker, you can easily get into this field. You won't need to work long to move up to the more senior positions. Even if you don't have any previous experience, you can learn new skills as you work. The following are the top jobs in manufacturing for beginners.

There are many reasons to choose a career as a manufacturer, but there are also key benefits. The salaries for manufacturing jobs are generally higher than the average for all jobs in Minnesota. Manufacturing workers average $70,860 annually, more than 10% more than the Minnesota median wage. You can also get promoted to these jobs by obtaining a high-school diploma or training on the job. The Manufacturing industry is great for anyone, whether you are a recent graduate or an experienced worker.

FAQ

Why is logistics important in manufacturing

Logistics are an integral part any business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

What types of jobs can you find in logistics

There are many types of jobs in logistics. Some examples are:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales reps - They sell products and services to customers.

-

Logistics coordinators: They plan and manage logistics operations.

-

Purchasing agents - They buy goods and services that are necessary for company operations.

-

Customer service agents - They answer phone calls and respond to emails.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers - They fill orders based on what is ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There is a variety of other jobs in logistics. These include transportation supervisors and cargo specialists.

What do you mean by warehouse?

A warehouse is an area where goods are stored before being sold. It can be either an indoor or outdoor space. In some cases it could be both indoors and outdoors.

Can certain manufacturing steps be automated?

Yes! Since ancient times, automation has been in existence. The wheel was invented by the Egyptians thousands of years ago. We now use robots to help us with assembly lines.

There are many uses of robotics today in manufacturing. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation can be applied to manufacturing in many other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing refers to a set of principles that improve the quality, speed and costs of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Lean manufacturing includes five basic principles:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. Many economists believe lean manufacturing will play a major role in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

It can be applied to any aspect of an organisation. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types:

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.