An industrial engineer uses engineering and testing to improve products. In product development, industrial engineers use shake tables to test entire products under varying temperatures, humidity, and vibrations. Failure data is used to improve manufacturing and engineering processes. Simple changes such as mold-resistant coatings can make a big difference in the quality and durability of a product. Even the smallest changes, such as a lock-washed placement, can improve a product's service life.

Job description

It is important to carefully craft your job description if industrial engineers are something you want to pursue. The most successful industrial engineers are the ones who can combine their technical expertise with people smarts, and an effective job description will help you attract the best candidates. You can get some inspiration for a job description by checking out engineering job listings on Monster. Your introduction should include a compelling paragraph that highlights the company's advantages to applicants. Your employer should be attractive to you, whether you are looking to join a well-respected brand, an innovative start up, or a young, dynamic company with a creative, open atmosphere.

Apart from having exceptional technical skills, industrial engineering requires excellent communication skills. Industrial processes involve multiple departments and people, so an industrial engineer needs to know how to interact with them all. An industrial engineer must be able to convince employees and managers that his or her methods will increase efficiency. Increasing productivity is usually a result of good relationship management. An industrial engineer job description does not require only technical skills.

Education requirements

An education in the field of industrial engineering is necessary for a position as this one involves a great deal of math and analytical skills. As they communicate their findings to others, industrial engineers must also have excellent communication skills. They must also be able design processes and designs that lower labor costs. This field can also be achieved through education. Here are some of the essential educational requirements for this position.

Industrial engineers require excellent communication skills and interpersonal skills in addition to a college education. They work closely with other professionals and act as the link between business and technical aspects of an organization. Industrial engineers must also have strong analytical and communication skills, so they can effectively communicate with business leaders and employees. This profession requires excellent problem-solving and leadership skills. Also, industrial engineers need to have high levels of technical proficiency and mechanical aptitude.

Career options

There are many career paths available for those who are interested in industrial design. Industrial engineers typically start in manufacturing. However, there are other options such as hospitals and government agencies. Industrial engineers can also work in the retail trade, educational agencies and professional trade associations. The list of possible jobs for industrial engineers is endless, but here are a few of the best. Find out if this is the right profession for you.

An industrial engineer can be focused on efficiency and effectiveness. Their job requires them to balance several factors such as time, number of workers needed, available technology, and actions workers must take. They must also be aware of safety and environment concerns. Many industrial engineers also participate in quality assurance and supply chain management. This is especially important as industries constantly look for ways to lower costs while increasing productivity. In addition, they can help to develop new product applications and optimize work flow throughout an organization.

Salary

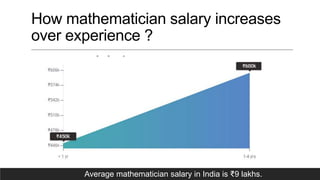

The average industrial engineer salary in 2004 was $87,513 US Dollars. This figure is expected to rise to $114,146 by 2020. The industry one works in will have a significant impact on how much you earn. Salaries in thriving industries are likely to receive larger raises. Industrial Engineers are subject to frequent changes and receive moderate bonuses. Most bonus recipients are involved in the revenue generation cycle. An industrial engineering degree is necessary to receive the best possible salary.

A bachelor's degree is required to be an industrial engineer. Some employers, however, prefer PhDs. In the U.S., an industrial engineer's salary ranges from $56,000 to $121,000, but that number can vary a great deal. Although an industrial engineer can work in an office environment, many jobs require overtime or protective clothing. And as a result, a high degree of flexibility is necessary.

FAQ

What kind of jobs are there in logistics?

Logistics can offer many different jobs. Here are some examples:

-

Warehouse workers: They load and unload trucks, pallets, and other cargo.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives - They sell products to customers.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents: They are responsible for purchasing goods and services to support company operations.

-

Customer service representatives - Answer calls and email from customers.

-

Shipping clerks: They process shipping requests and issue bills.

-

Order fillers - They fill orders based on what is ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

What are the four types of manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. It involves many different activities such as designing, building, testing, packaging, shipping, selling, servicing, etc.

What is the role and responsibility of a Production Planner?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They also ensure the quality of the product and service meets the client's requirements.

How important is automation in manufacturing?

Automation is essential for both manufacturers and service providers. It allows them provide faster and more efficient services. It reduces human errors and improves productivity, which in turn helps them lower their costs.

What is it like to manage a logistics company?

A successful logistics business requires a lot more than just knowledge. For clients and suppliers to be successful, you need to have excellent communication skills. You should be able analyse data and draw inferences. You need to be able work under pressure and manage stressful situations. You must be creative and innovative to develop new ideas to improve efficiency. You must be a strong leader to motivate others and direct them to achieve organizational goals.

You must be organized to meet tight deadlines.

What are manufacturing & logistics?

Manufacturing refers the process of producing goods from raw materials through machines and processes. Logistics includes all aspects related to supply chain management, such as procurement, distribution planning, inventory control and transportation. Manufacturing and logistics can often be grouped together to describe a larger term that covers both the creation of products, and the delivery of them to customers.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

Six Sigma in Manufacturing:

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. The main goal of Six Sigma is to reduce variation from the mean value of production. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have this understanding, you will need to identify sources and causes of variation. These variations can also be classified as random or systematic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. Random variations would include, for example, the failure of some widgets to fall from the assembly line. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

After identifying the problem areas, you will need to devise solutions. It might mean changing the way you do business or redesigning it entirely. Once you have implemented the changes, it is important to test them again to ensure they work. If they fail, you can go back to the drawing board to come up with a different plan.