Additive manufacturing is a manufacturing technique that uses digital files to create parts, objects, or whole systems. It allows firms to create complex machinery or other devices at very low costs. In addition, the process reduces production expenses and time to market. It does not require casting, forging or any other traditional production method.

In additive manufacturing, the benefits go far beyond suppliers, manufacturers, and communities. They also benefit consumers who can purchase products that are innovative. Many Fortune 500 companies have already adopted 3D printing technology. Biden Administration launched a new initiative to assist small and medium-sized manufacturers in adopting additive production.

AM Forward is a public-private initiative that aims to encourage the use of additive manufacturing by developing standards and common practices, establishing an open-market for additive-manufactured parts, and addressing supply chain issues. It is led by five large U.S. manufacturers: General Electric Aviation, Honeywell, Lockheed Martin, Raytheon, and Siemens Energy. These firms are partnering with the DOE Manufacturing Demonstration Facility at Oak Ridge National Laboratory, which is a national facility that provides access to a range of additive-manufacturing technologies.

OEMs will work with other firms to create standard specifications and develop technical solutions for industry challenges. They will also offer technical assistance to U.S. suppliers through the AM Forward Pact. The initiative is expected to be extended to other large companies in the coming years.

One of the major players involved in AM Forward is the NEO Additive Manufacturing Cluster of Ohio, which works to accelerate the adoption of additive-manufacturing technologies. Ohio has a large pool of scientists and engineers, making it a great location for additive manufacturing companies.

The America Makes national accelerator is another important player. This program partners with academia, industry, economic development resources, and workforce training programs to encourage the adoption of additive-manufacturing by a wide range of sectors. Many university programs now exist for additive-manufacturing.

Other government programs are available to help with the adoption of additive production, such as the Manufacturing Extension Partnership. The Department of Labor has other programs that can be used to assist small-scale manufacturers, such as technical support or financing.

These programs often help overcome market failures. Small manufacturers may face many obstacles that prevent them from obtaining affordable financing or access to the latest industry-standard technology. Similarly, some customers may not be willing to commit to purchasing from companies that invest in additive-manufacturing technologies.

Some of the most innovative additive-manufacturing firms in the country are located in Ohio. Desktop Metal is an industrial additive-manufacturing company that offers metal 3-D printing and machining services to manufacturers and designers. Jonco Industries, Inc. offers a range of fabrication services, such as rapid prototyping, design and prototyping, and high volume surface finishing. PostPro3D specialises in automated surface finish.

Besides collaborating with the Federal Government, other industry organizations are working to increase the adoption of additive-manufacturing. The Fraunhofer Institute is a leading institution for the development of additive-manufacturing technology.

FAQ

What does warehouse refer to?

A warehouse, or storage facility, is where goods are stored prior to being sold. It can be indoors or out. It may also be an indoor space or an outdoor area.

Why is logistics important in manufacturing?

Logistics are an essential component of any business. They are essential to any business's success.

Logistics play an important role in reducing costs as well as increasing efficiency.

What is the role and responsibility of a Production Planner?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They ensure that the product or service is of high quality and meets client requirements.

What is the job of a logistics manger?

A logistics manager ensures that all goods are delivered on time and without damage. This is done by using his/her experience and knowledge of the company's products. He/she should make sure that enough stock is on hand to meet the demands.

What does it take for a logistics enterprise to succeed?

It takes a lot of skills and knowledge to run a successful logistics business. You must have good communication skills to interact effectively with your clients and suppliers. You must be able analyze data and draw out conclusions. You must be able manage stress and pressure under pressure. In order to innovate and create new ways to improve efficiency, creativity is essential. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

You must be organized to meet tight deadlines.

Can we automate some parts of manufacturing?

Yes! Yes! Automation has existed since ancient times. The Egyptians invented the wheel thousands of years ago. Nowadays, we use robots for assembly lines.

In fact, there are several applications of robotics in manufacturing today. They include:

-

Robots for assembly line

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that make products

Automation could also be used to improve manufacturing. 3D printing makes it possible to produce custom products in a matter of days or weeks.

How can manufacturing efficiency improved?

First, we need to identify which factors are most critical in affecting production times. We must then find ways that we can improve these factors. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you have identified the factors, then try to find solutions.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

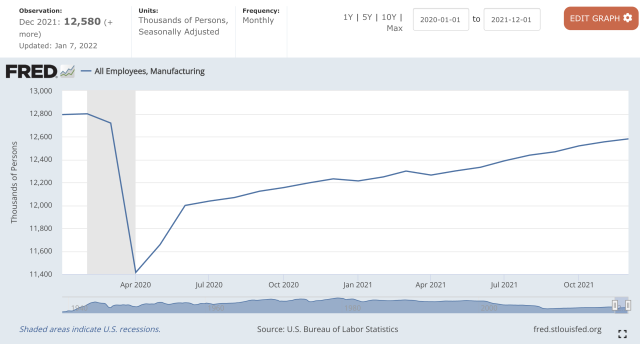

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department, Tokyo, Japan, developed it in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma aims to reduce variation in the production's mean value. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you understand that, it is time to identify the sources of variation. This will allow you to decide if these variations are random and systematic. Random variations occur when people do mistakes. Symmetrical variations are caused due to factors beyond the process. If you make widgets and some of them end up on the assembly line, then those are considered random variations. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. You might need to change the way you work or completely redesign the process. After implementing the new changes, you should test them again to see if they worked. If they don't work you need to rework them and come up a better plan.