During the Great Recession, the manufacturing industry lost nearly 2 million jobs. While the industry has gained some ground, job growth has been slow. There are still several headwinds facing manufacturing, including higher prices, tariffs, and the fading impact of the 2017 tax cuts for corporations. The slow global growth is compounding these problems.

Manufacturing industry is diverse. Jobs in the industry include technical, manufacturing, administrative, and entertainment jobs. These jobs are often hands-on. Manufacturing workers, for example, are responsible for packaging and assembling a variety products for sale. They are responsible for monitoring production and transporting raw materials. Additionally, they can work in science, math, technology, or mathematics.

In addition to traditional manufacturing, there are also jobs in advanced manufacturing. These jobs require high-level technical skills, which may also be useful in other industries. Advanced manufacturing employers may offer benefits and training opportunities, such as apprenticeships. These employers may also offer high wages. They can be difficult to find. Employers might be encouraged to offer high-skilled manufacturing jobs in times of labor shortage.

One of the most exciting aspects of the manufacturing industry is the diversity of roles. You can work in manufacturing plants, power plants, and bakeries. As well as performing administrative tasks, such managing a production group, workers may be involved in administrative tasks. They could also work in food processing plants, such as meat cutters, fish cutters and batchmakers.

While there are many occupations to choose from in the manufacturing industry, the best opportunities are often found in professional and managerial roles. High school diplomas are the minimum education needed for most production jobs. A bachelor's degree, however, is more preferred. It is also desirable to have a technical education, particularly for jobs in manufacturing, where many workers will need to operate plant machinery. In addition, jobs in the science and technology industries have seen recent growth.

Production jobs are a great way to show off your talents. If you are looking for a career in film, video, or animation, you might consider offering to work for free at a production company in exchange for references. This can provide valuable experience that can lead to rewarding connections. To determine if there is a demand for your skills, it is a good idea to research the local production industry. Find out if you are eligible for a entry-level job in production.

Multiple research studies have shown that the number of workers in temporary jobs has increased dramatically in the production sector. The Great Recession is a major reason for this increase in temporary workers. Construction and healthcare have both seen a decrease in their need for temporary workers over the past five years. However, the computer and mathematical sectors have seen an increase in the use of these workers. However, manufacturing's use has increased nearly twice in the same time frame.

The production industry also has a number of other interesting jobs, including audio engineers and sound technicians. In addition, the industry has seen a small increase in the number of women working in manufacturing jobs. The percentage of women in the production industry has increased 5.3 percentage points over the past year. The industry's women workers have not seen an increase in their numbers at the same time as men. This may be due in part because the majority of those in the industry work in support roles.

FAQ

What are the products of logistics?

Logistics refers to all activities that involve moving goods from A to B.

They encompass all aspects transport, including packaging and loading, transporting, storage, unloading.

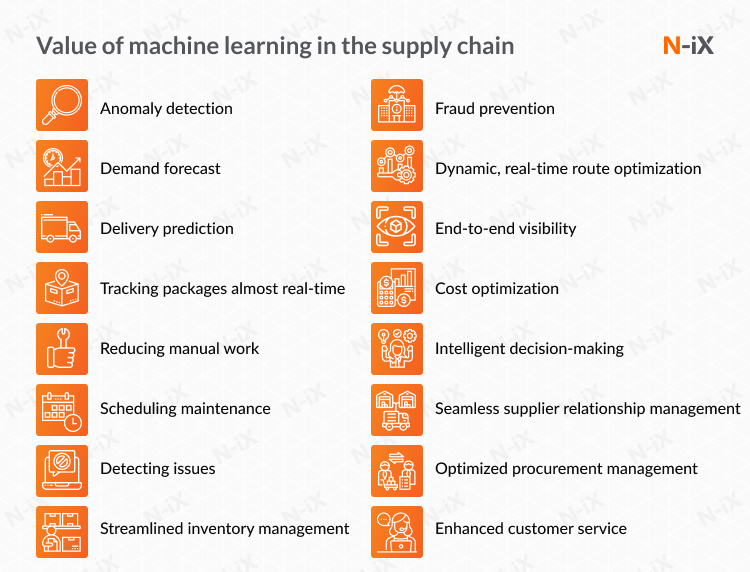

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. Logisticians help companies improve their supply chain efficiency by providing information about demand forecasts and stock levels, production schedules, as well as availability of raw materials.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

What does manufacturing industry mean?

Manufacturing Industries are businesses that produce products for sale. The people who buy these products are called consumers. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They produce goods from raw materials by using machines and other machinery. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

What are the 4 types of manufacturing?

Manufacturing refers the process of turning raw materials into useful products with machines and processes. Manufacturing can include many activities such as designing and building, testing, packaging shipping, selling, servicing, and other related activities.

What does "warehouse" mean?

Warehouses and storage facilities are where goods are kept before being sold. It can be an outdoor or indoor area. It may also be an indoor space or an outdoor area.

How can I find out more about manufacturing?

Experience is the best way for you to learn about manufacturing. However, if that's not possible, you can always read books or watch educational videos.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Lean manufacturing is widely used in many industries. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Lean manufacturing is based on five principles:

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses are now using lean manufacturing to improve their competitiveness. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types of lean manufacturing:

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous improvement refers to continuous improvement of processes as well people and tools.