A process technician is responsible for working on a manufacturing plant's equipment. To troubleshoot or maintain equipment, they use science, math, chemistry and computer operation. A process technician is required to maintain company quality standards.

Some Process Technicians work at a laboratory. These technicians carry out experiments, draw conclusions and make recommendations for improvement. They may also help train others. It may be advantageous to have a background or education in engineering or biochemistry depending on the job.

Most Process Technicians work at a factory. They can also work in other industries. They can be found in water treatment plants where they are responsible for providing clean drinking water. They need to be able observe and solve problems.

The safety of the work place is the responsibility of Process Technicians. They must maintain the plant equipment in a safe condition and adhere to safety policies. Process Technicians are responsible for repairing or replacing damaged equipment if a machine or automation goes down.

Process technicians often work in shifts. Some industries work 24-hours, which may mean some process technicians need to work weekends and on holidays. Process technicians must be flexible and adaptable to work in different environments.

A skilled Process Technician is capable of solving the problems and challenges that come with their work. A strong skill set will allow them to produce the highest quality products.

This is a great place to start if you are looking for a career. These courses can be in mathematics, physics, and chemistry. You may also want to consider taking additional certifications.

Employers may require that you have a formal education. A process technology associate's degree may prove useful. This will give a foundation in physics and mathematics as well as engineering. Some employers will require that you have a bachelor's. You could be able to pursue a leadership role in this field with a bachelor's.

If you are applying for a job at Process Technician, make sure to list all of your relevant experience. Your manager may also be interested in additional certifications. A higher salary can be achieved by obtaining the right education.

The communication skills required for Process Technicians are essential. This will include writing reports and communicating with clients and technical personnel. Additionally, you might be required participate in safety meetings.

Process technicians are also trained in recognizing and minimising defects. Their work is critical to pharmaceutical companies' ability to make medicine safely. They might be involved in testing machines or materials or performing a range other tasks.

A process technician can help improve their job outlook, and even increase their salary. They could be eligible for a variety of jobs, such as Quality Control Technician and Production Supervisor.

To start a career as a Process Technician, you should have a solid foundation in math, chemistry, and science. Your knowledge can be furthered through education and volunteer experiences. Continuing your education can also help you stay up to date with the latest technology.

FAQ

What are the responsibilities for a manufacturing manager

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They must also be alert to any potential problems and take appropriate action.

They must also be able to communicate with sales and marketing departments.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

What are the products and services of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians ensure the product reaches its destination in the most efficient manner. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

What does the term manufacturing industries mean?

Manufacturing Industries are companies that manufacture products. Consumers are those who purchase these products. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They produce goods from raw materials by using machines and other machinery. This includes all types if manufactured goods.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

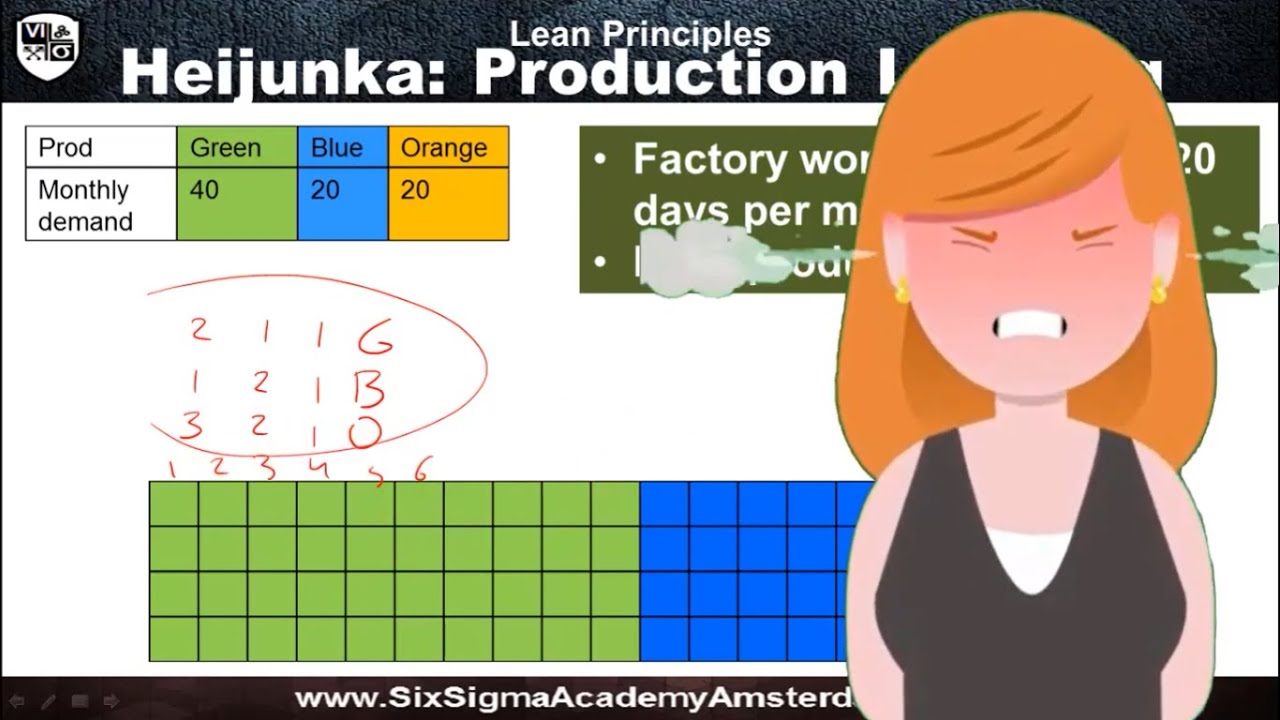

Six Sigma: How to Use it in Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding how variability works in your company is the first step to Six Sigma. Once you've understood that, you'll want to identify sources of variation. These variations can also be classified as random or systematic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. Random variations would include, for example, the failure of some widgets to fall from the assembly line. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. It might mean changing the way you do business or redesigning it entirely. To verify that the changes have worked, you need to test them again. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.