Six sigma principles are important for improving efficiency and productivity within an organization. They also improve the quality of products and reduce costs. The process can be done through various strategies and methodologies, such as process mapping, statistical analysis, and control charts.

What are 6 Sigma principles?

The 6 sigma principles are a set of methods used for identifying and eliminating defects in manufacturing processes. The results are often huge. They can be applied in a variety of ways. It is also a good way to make sure all processes are running smoothly and efficiently.

Lean six sigma:

The first principle of lean six sigma is to understand the real workflow. It means you must observe the process, take notes and then determine what improvements can be made. This is an important step, as it allows you determine the problem in order to create a suitable solution.

This principle is crucial for any project and is even more important when it comes to process improvement. This is because it's hard to make a change if you have a clear idea of what needs improvement but no clue how to fix it.

It may be necessary for a company to change the way it works or how its employees approach a task in order to improve its process. It can be difficult to change a process, but with the right attitude, it can be done quickly and efficiently.

Six sigma is built on the principle that employees should be empowered to take part in a project. It can be difficult to implement changes when only the upper management is involved.

In addition to ensuring that all employees are onboard with the changes, it is important that they are trained in the specific principles of the process so that they can identify and eliminate errors or defects. The employees should be provided with the tools and resources needed to take part in the project.

What are the six sigma values?

Six Sigma values emphasize the importance of customer satisfaction, the belief that all processes should be designed with a minimum amount of waste and the emphasis on data collection and analysis. All of these factors contribute to an increased level of customer loyalty and satisfaction.

The six sigma values also include consistency and reliability. These factors are vital in an industry where there is a high demand for quality products and services. These should be implemented in every aspect of the company.

Summary: The six-sigma values can help an organization improve its operations and become more effective. They are also important for creating a sustainable system that will allow the company to grow and succeed. These are great ways to keep the company competitive and profitable.

FAQ

What are manufacturing and logistics?

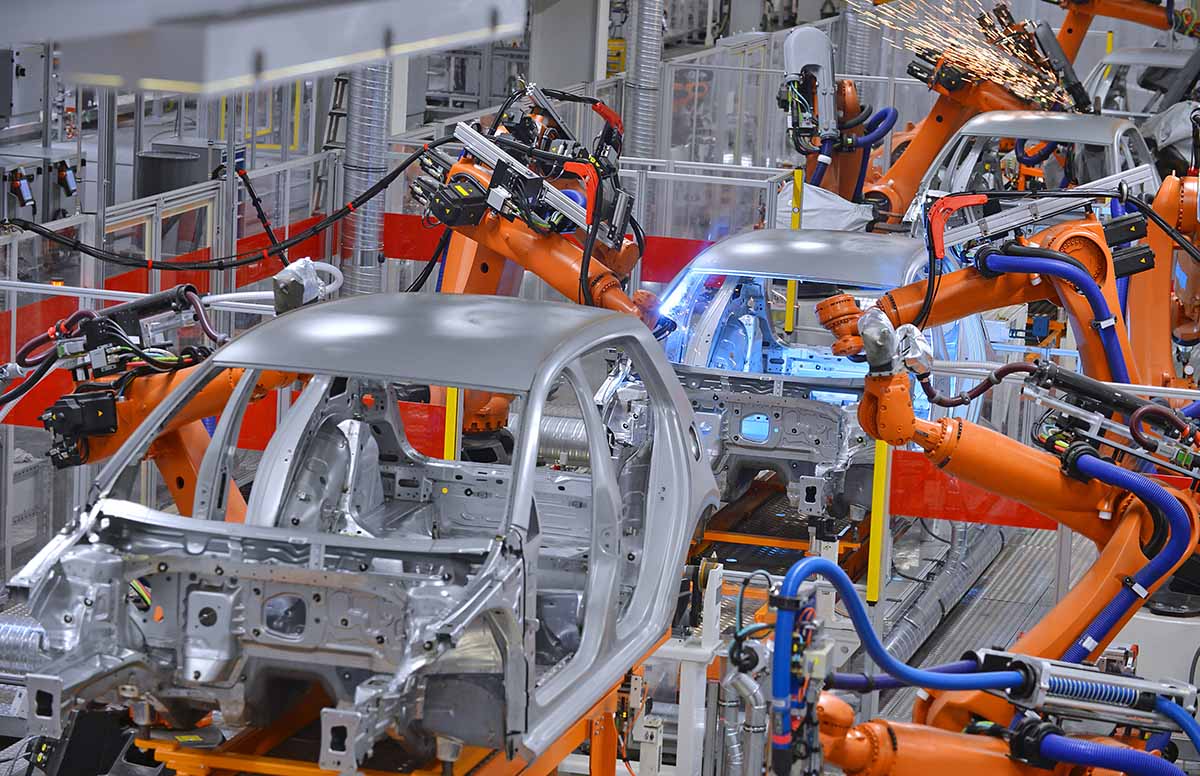

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. Manufacturing and logistics can often be grouped together to describe a larger term that covers both the creation of products, and the delivery of them to customers.

Why is logistics important in manufacturing?

Logistics are essential to any business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics play a key role in reducing expenses and increasing efficiency.

What does the term manufacturing industries mean?

Manufacturing Industries are businesses that produce products for sale. Consumers are the people who purchase these products. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They produce goods from raw materials by using machines and other machinery. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. No. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use the Just In Time Method in Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It's the process of obtaining the right amount and timing of resources when you need them. This means that you only pay for what you actually use. Frederick Taylor was the first to coin this term. He developed it while working as a foreman during the early 1900s. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He realized that workers should have enough time to complete their jobs before they begin work. This would help increase productivity.

JIT is a way to plan ahead and make sure you don't waste any money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. If you expect problems to arise, you will be able to provide the necessary equipment and personnel to address them. This way you won't be spending more on things that aren’t really needed.

There are different types of JIT methods:

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow for you to track the material that you have left after using it. This will let you know how long it will be to produce more.

-

Inventory-based : You can stock the materials you need in advance. This allows you predict the amount you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based JIT: This type of JIT is most commonly used. You allocate resources based on the demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based: Another variation of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based JIT is another variant of resource-based JIT. Instead of thinking about the cost of each employee or the time it takes to produce something, you focus on how good your product quality.

-

Value-based JIT: This is the latest form of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. It is used when production goals are met while inventory is kept to a minimum.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It's important because it reduces lead times and increases throughput.